Description

Technical Specifications

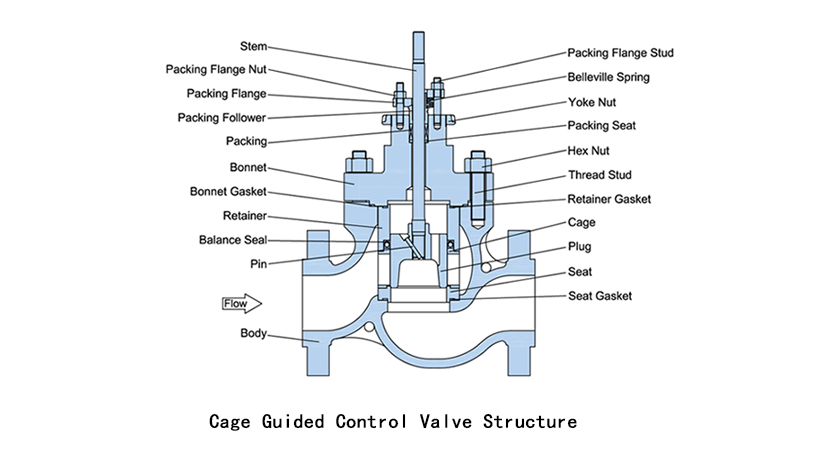

SPECS Cage Guided Control Valves have large Cv value, and of excellent dynamic stability. It is suitable for heavy duty services. Only a small operation force can achieve stability control due to the balanced fluid pressure structure on plug. For those severe fluid conditions that cannot be covered by this series, please select Specs Valve multi stage type Control Valves.

Applicable Standard

Design & Manufacture Standard: IEC 60534-2006

Face to Face: ISA-75.03-1992

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: IEC60534-4

Products Range

Size: 1 1/2"~24"

Pressure Rating: ASME CLASS 150~2500

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: Flanged (RF, RTJ), Butt Weld, Socket Weld.

Temperature Range: -196℃~550℃

Seat Leakage: ANSI Ⅳ(0.01%) or Ⅵ(bubble-tight)

Bonnet Type: Standard, Fin-Extension, Long-Extension, Bellows, Steam Jacket

Design Features

1. The third generation of S-type smooth casting body cavity gets greater circulation ability to reduce the initial investment, as it is now with more efficient average flow velocity by improving the second generation through CFD (Computational Fluid Dynamics)

2. In accordance with ASME, valve body and the upper bonnet are pressed together by the double-head stud bolt

3. The stability of plug movement are improved due to the strong cage guide and the unique balanced sealing ring (GF TFE structure for room temperature, graphite 1398 & Graph-lock structure for high temperature), so that the vibration and mechanical noise are reduced

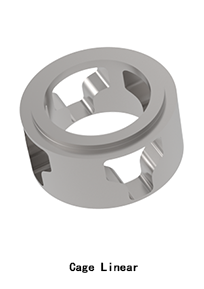

4. With the solid cage, valve body are protected from steam and cavitation damage. There was a S streamlined channel and this makes small loss of pressure drop, high flow, wide range of control.

Benefits

1. Compared with un-balanced single seated straight through valve, the equipped actuator can be smaller for the balanced structure plug, however, it can overcome higher pressure difference and with better price

2. The flow characteristics can be changed by different cage window shape, and this promote the parts commonality.

3. Noise can be reduced by 10dB compared with the ordinary single/double seated control valve

4. Easy and fast replacement for valve parts even when the valve body is in the pipeline, this makes maintenance easier. The valve parts of standard cage can be easily replaced by the multi-hole cage in order to apply for different conditions, and this can ensure the out flow is within the security range to prevent cavitation and reduce the noise.

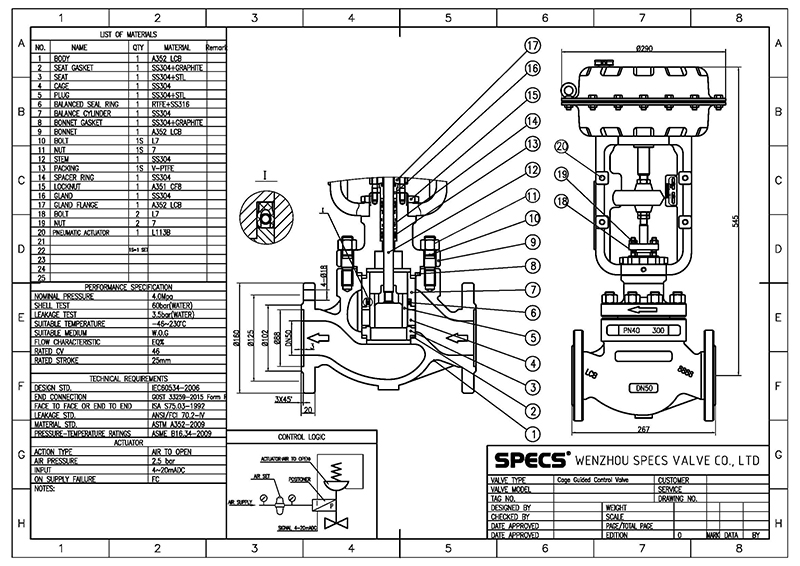

The GA Of Cage Guided Control Valve

Body part selection map

Various flow characteristics are optional

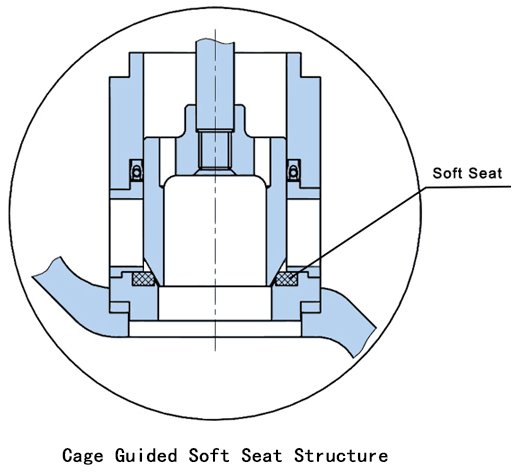

Soft seat structure

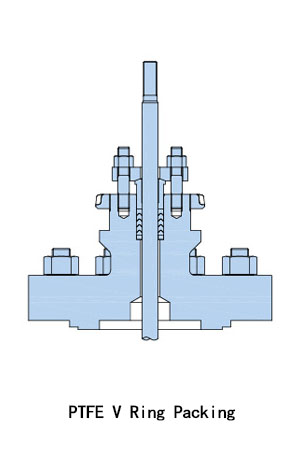

Control valve packing

Most control valves use packing boxes with the packing

retained and adjusted by a flange and stud bolts. Several packing materials can

be used depending on the service conditions expected and whether the

application requires compliance to environmental regulations. There are 3

common packing types as follows:

PTFE V Ring Packing

Molded in V-shaped rings, packing

lubrication not required.

Resistant to most known chemicals.

Recommended working temperature

range:−40 to +230°C

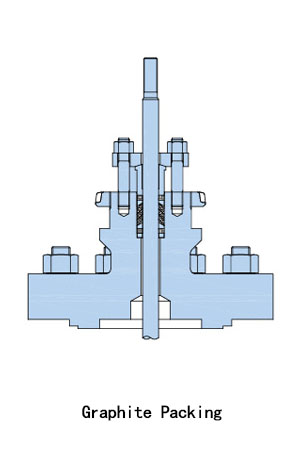

Graphite Packing

This packing system is designed

primarily for high temperature applications。

Recommended working temperature range: +230 to +450°C

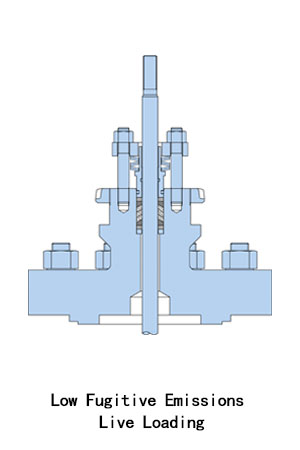

Low Fugitive Emissions Live Loading